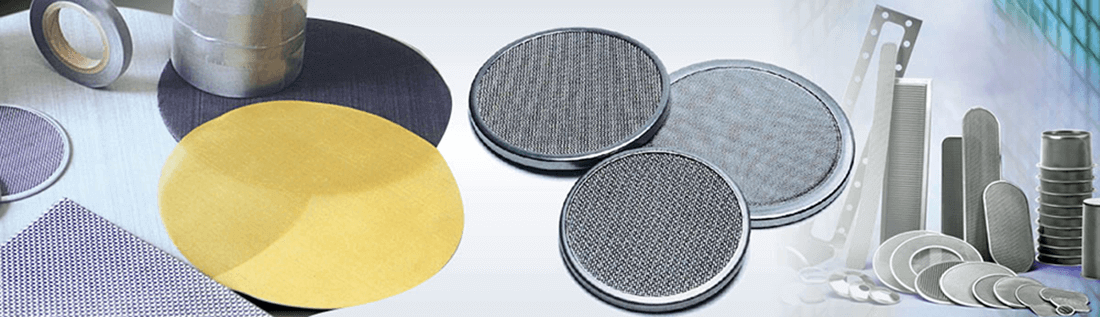

Extruder screen is used for Extrusion equipment ,An important part of plastic and rubber processing machinery .its our main product,In 2001 year,We have bought five advanced production facilities for produce it .After fifteen years of production ,we can produce extruder screen for PE, PP,plastic extruder,plastic recycling equipment,plastic granulator, blowing, blow molding and other uses,for packing factory, plastic factory,rubber factory etc.

1.Material

SUS304, SUS316, SUS316L, NO.201, NO.304, NO.316 stainless steel, also nickel alloy, Hastelloy alloy, Monel and Inconel.

2.Edge

Aluminum or non-framed.

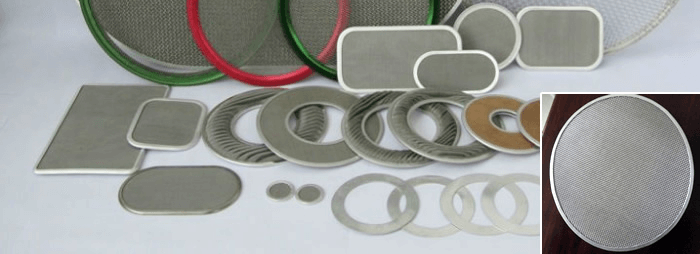

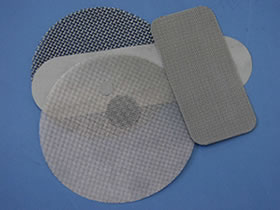

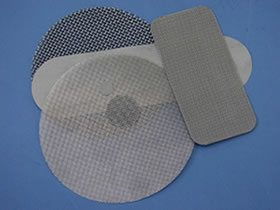

3.Shape: Circle,disc,square,oval,rectangular,kidney,cones and other special shape

Note:When choose filter mesh,the working environment must be taken into consideration.

4.Benifits of our extruder screen:

High filtration precision,

High strength,

Easy cleaning,Simple replacement,

Hi-tem resistance,

Corrosive resistant.

5.Multilayer Extruder Screen Packs

The screen packs made from several screens of different mesh sizes by welded them together.Because the screen is overlapped and staggered, the filter accuracy and the amount of dirt can be improved.

6.Multilayer Extruder Screen Features

Multi-layer extruder screen filter packs are extra strong, sturdy and convenient for problem free processing;

Can be assembled in proper sequence to eliminate operator error;

The screen pack even prevents any foreign particles in the molten mass from going through the extrusion process;

This type of extruder screen is suitable for fine extrusion, and it makes extrusion more clean and clear.

Multi-layer extruder wire mesh screen filter packs

Layers :2-5 layers, or other more layers.

Material: Stainless steel plate, copper plate, galvanized sheet, aluminium plate

Shapes: round, oval, rectangle, elliptical shape

Packs Diameter 20mm - 900mm

Frame style: with and without frame and spot welding

Standard Extruder Screen Filter Media Specification | |||

| SS Mesh | Wire Dia. mm | Aperture Size mm | Open Area |

10 X 10 | 0.711 | 1.829 MM | 51.8 |

14 X 14 | 0.457 | 1.357 MM | 55.9 |

16 X 16 | 0.457 | 1.131 MM | 50.7 |

20 X 20 | 0.457 | 0.813 MM | 41.0 |

24 X 24 | 0.376 | 0.682 MM | 41.4 |

30 X 30 | 0.376 | 0.531 MM | 34.2 |

30 X 30 | 0.310 | 0.536 MM | 40.0 |

40 X 40 | 0.274 | 0.361 MM | 32.3 |

50 X 50 | 0.193 | 0.335 MM | 43.6 |

60 X 60 | 0.193 | 0.230 MM | 29.8 |

80 X 80 | 0.122 | 0.196 MM | 37.9 |

100 X 100 | 0.102 | 0.152 MM | 36.0 |

120 X 120 | 0.091 | 0.120 MM | 31.8 |

150 X 150 | 0.071 | 0.088 MM | 29.6 |

200 X 200 | 0.050 | 0.077 MM | 36.76 |

300 X 300 | 0.040 | 0.045 MM | 27.83 |

325 X 325 | 0.035 | 0.043 MM | 30.49 |

400 X 400 | 0.028 | 0.036 MM | 31.25 |

FAQ

Can you explain the knowledge of the extruder screen?

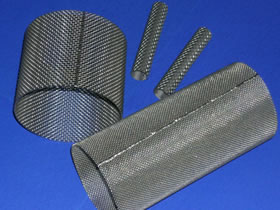

Extruder screen types are mainly mesh discs, leaf filters, spot welded mesh packs, rim or framed packs, cylinders or tube filters.

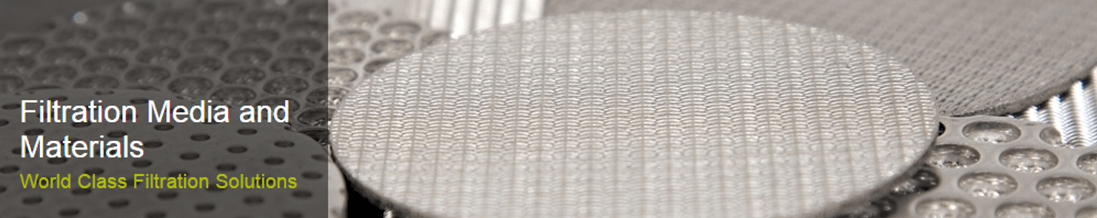

It is made by wire mesh cloth processed into single layer or multi-layer pieces with optional frames. Metal Mesh Extruder Screen Filter is applied to provide a clean and clear melt filtration for plastic and rubber processing machinery.

Filter Media commonly used are Stainless Steel Wire Cloth Woven or Sintered. The wire cloth is cut or punched into pieces or discs first, then compressed with multi-layers into screen packs and other forms.

In plastic extrusion, stainless steel extruder screen is designed for PP, PE and other plastic hot-melt extruding processes. The fine mesh Dutch Weave Wire Cloth Layer together with a Plain Weave Square Mesh support layer forms screen packs are used for preventing impurities in fine extrusion. It is effect to keeps away mixing of foreign particles in finally equipped extrusion product.

Featured Mesh Screen and Filter Strainers, Processed from Stainless Steel Woven Wire Mesh Cloth SUS302, 304, 304L, 316 and 316L:

• Spot Welded Circle or Round Disc Extruder Screens, to be placed into extruder head

• Cylinder Extruder Screen for Thermoplastic polymers

• Leaf Filters

• Multilayer Woven Wire Mesh Extruder Screen Packs of Dutch Weave Wire Cloth Plus Plain Weave Support Filter Mesh

• SS Wire Mesh Filter Disks, with thin frame or rims

• Dutch Reverse Weave Mesh Continuous Filter Belts

• Pleated Candle Filters

• Stainless Steel Wire Mesh Strainers