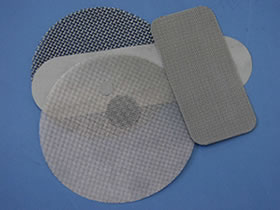

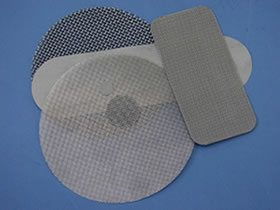

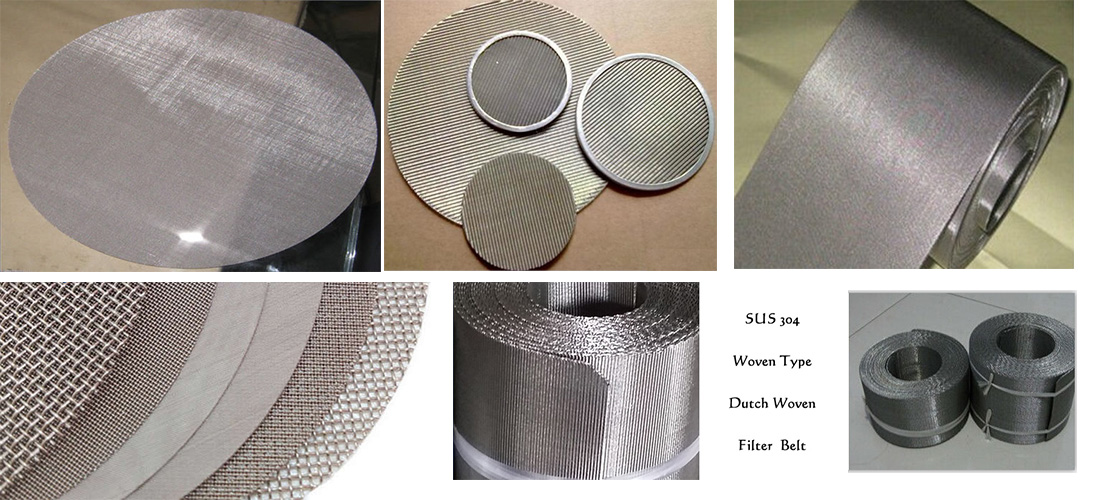

Product : Filter disc,Filter mesh

Material : SUS 301, 302, 304, 304L, 316, 316L

Filter media : Single layer or multilayer

Filtration accuracy : As your need

Size : As your need

Mesh : 10*10 14*14 20*20 80*80 150*150 etc. Or as your need

Shape : As your need

Packing : plastic and wooden

Produce time : 5 days

MOQ : 1000 PCS

Extruder screens provide a clean and clear extrusion for the melt filtration and plastic extrusion processing machinery. This pack screen filter is designed to keep away mixing of foreign particles in finally equipped extrusion product. Also called polymer filter or melt filter screen. Extruder Screen Mesh packs are mainly made from high quality SS 316, SS304L meshes ranging from 4 mesh to 500 mesh up to 5 microns, and used for Plastic and Rubber Industry. Their edges styles cover spot welded edges and aluminum framing around the spot welded edges.

Major types:

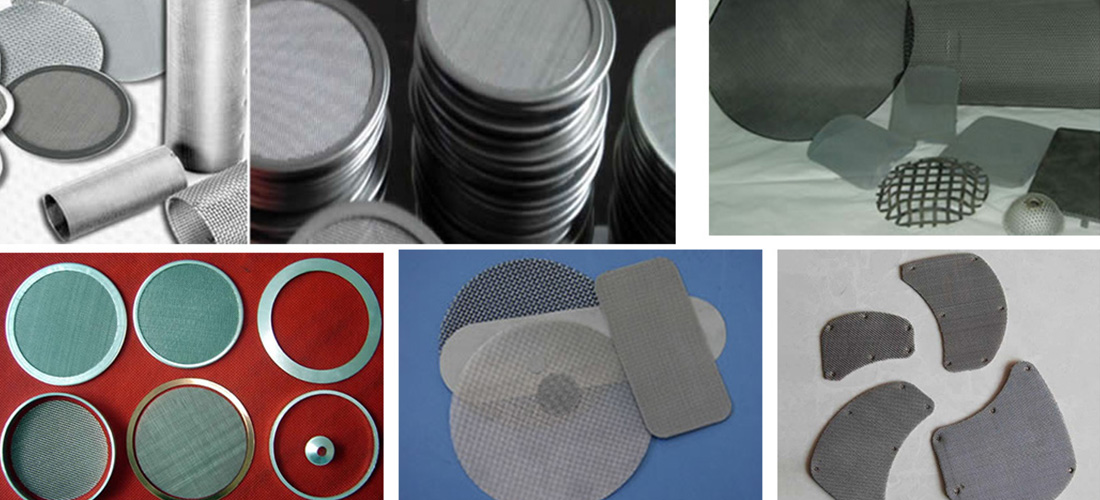

Extruder screen filter disc, circular screen, Multilayer extruder screen packs. Spot welded and with or without aluminum frame Layer: single layer or multilayer.

Edge:

Aluminum framed or non-framed.

Shape:

Circle, disc, square, oval, rectangular, kidney, cones and other special shape

Material of the filter screen/ filter mesh: SUS304(AISI304), SUS316(AISI316), SUS316L(AISI316L), NO.201, NO.304, NO.316 stainless steel, also nickel alloy, Hastelloy alloy, Monel and Inconel.

Extruder screen packs materials are mainly standard steel, stainless steel and nickel alloys. stainless steel screen packs are much more resistant to rust than others. While packs from nickel alloy can be used in corrosive processing environment (such as from sulfuric acid, hydroflouric acid, and salt water). When choose screen packs, the working environment must be taken into consideration. Stainless Steel Extruder Screens are widely applied on PC, PP, PE, PS, HIPS, PET, PVC and other plastic sheet extruder, the membrane machine, granulator, and nonwoven fabrics, color masterbatch, filler, leather chemical fiber extruder, etc.

Benifits of our filter screen packs: High filtration finness/precision; High intensity; Easy to clean; Easy to replace; High temperature resistant; Corrosive resistant.

Typical Type:Multilayer Wire Mesh Extruder Screen Packs

The screen packs made from several screens of different mesh sizes by welded them together. In the different mesh size screens, the finest wire screen is in the center of the pack, and the larger mesh opening screen is successively placed outer sides. The multi-layer extruder screens are arranged in a symmetrical fashion, which prevents the screen pack from accidentally being installed backwards. The multi-layer mesh screen packs are suitable for extrusion processing of plastics, polymers and fibers.

Regarding multi-layer mesh discs, the number and arrangement of welding spots can be produced according to your specific requirements. We can produce multi-layer mesh discs with welds. For example: plain steel wire mesh and stainless steel wire mesh can be welded together. Multi-layer extruder wire mesh screen filter packs are the different wire meshes cut to desired shapes and sizes, and then assembled properly and spot welded with each other to form multilayer packs.

Features:

Multi-layer extruder screen filter packs are extra strong, sturdy and convenient for problem free processing;

Can be assembled in proper sequence to eliminate operator error;

The screen pack even prevents any foreign particles in the molten mass from going through the extrusion process;

This type of extruder screen is suitable for fine extrusion, and it makes extrusion more clean and clear.

Multi-layer extruder wire mesh screen filter packs

Layers :2 , 3 ,4, 5 layers, or other more layers.

Material: Stainless steel(ss302, ss304, ss316, ss316L) woven wire cloth, copper wire cloth, galvanized wire mesh, aluminum alloy, and nickel alloys.

Shapes: round, oval, rectangle, elliptical shape

Packs Diameter 20mm - 900mm

Frame style: with and without frame and spot welding

Typical Type: Disc Type Wire Mesh Filter Screen / Circular Screen

Material of filter:

SUS 301, 302, 304, 304L, 316, 316L stainless steel wire mesh, brass wire mesh, plain steel wire mesh galvanized wire mesh etc.

Diameter of wire mesh discs: from 2--30".

Features:

Neat and precise, without bug; Regulate and precise mesh; Reliable filtering precision; High compressive strength; Hot-resistance and rust-resistance; Wear-resistance; Good moulding.

Application:

It is widely used in filtering of gas and liquid, separating of oter medium, precise stress filter, fuel filter, vacuum filter, etc. it is widely used in the field of petroleum, chemical industry, chemical fiber, rubber, metallurgy, medicine and food. It also has different sizes and bears the advantages of acid-resistance, alkali-resistcance, hot-resistance, high tensile strength, wear-resistcance, etc.

Typical Type: 301 Stainless Steel Extruder Screens Polymer Melt Filter

Material: Stianless steel Wire Mesh (SS 201,202,304,304L, 316,316L, 321, 430 etc)

Wire diameter: 0.028~0.711mm

Mesh: 10~400Mesh

Shape: round and disc. Usage: Filters, chemical industry, mine industry, paper-making,etc.

Hengmao circular filter screen comes with smooth screening surface with no sharp edges, burrs or acute angles, high durability, stable under tension and are uniformly cut by specifically developed power press, to avoid uneven edge. We assure to provide, circular screens which are customized resulting in absolute no wastage.

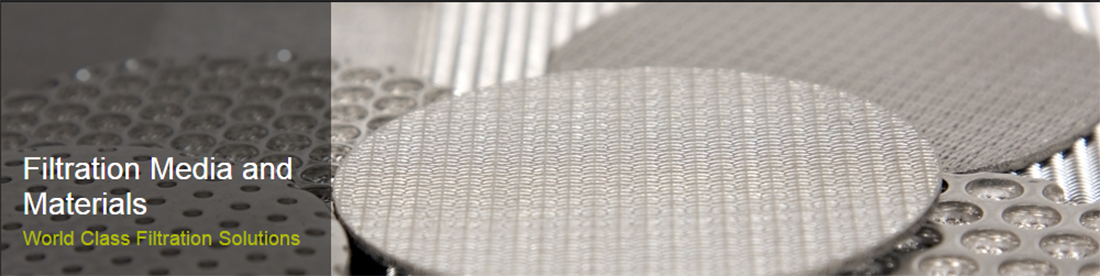

Filter Media: Stainless Steel Wire Mesh Weave Type

Standard Extruder Screen Filter Media Specification | |||

SS Mesh | Wire Dia. mm | Aperture Size mm | Open Area |

10 X 10 | 0.711 | 1.829 MM | 51.8 |

14 X 14 | 0.457 | 1.357 MM | 55.9 |

16 X 16 | 0.457 | 1.131 MM | 50.7 |

20 X 20 | 0.457 | 0.813 MM | 41.0 |

24 X 24 | 0.376 | 0.682 MM | 41.4 |

30 X 30 | 0.376 | 0.531 MM | 34.2 |

30 X 30 | 0.310 | 0.536 MM | 40.0 |

40 X 40 | 0.274 | 0.361 MM | 32.3 |

50 X 50 | 0.193 | 0.335 MM | 43.6 |

60 X 60 | 0.193 | 0.230 MM | 29.8 |

80 X 80 | 0.122 | 0.196 MM | 37.9 |

100 X 100 | 0.102 | 0.152 MM | 36.0 |

120 X 120 | 0.091 | 0.120 MM | 31.8 |

150 X 150 | 0.071 | 0.088 MM | 29.6 |

200 X 200 | 0.050 | 0.077 MM | 36.76 |

300 X 300 | 0.040 | 0.045 MM | 27.83 |

325 X 325 | 0.035 | 0.043 MM | 30.49 |

400 X 400 | 0.028 | 0.036 MM | 31.25 |

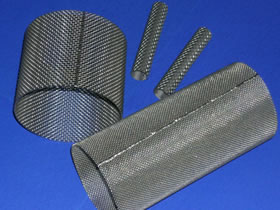

Extruder screen types are mainly mesh discs, leaf filters, spot welded mesh packs, rim or framed packs, cylinders or tube filters.

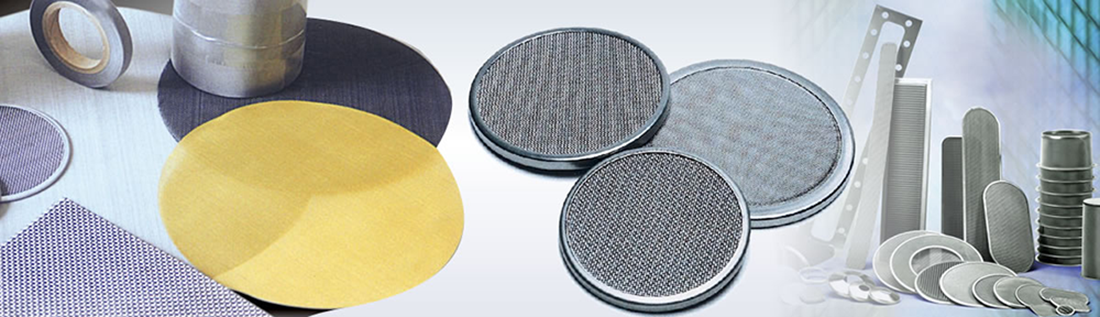

It is made by wire mesh cloth processed into single layer or multi-layer pieces with optional frames. Metal Mesh Extruder Screen Filter is applied to provide a clean and clear melt filtration for plastic and rubber processing machinery.

Filter Media commonly used are Stainless Steel Wire Cloth Woven or Sintered. The wire cloth is cut or punched into pieces or discs first, then compressed with multi-layers into screen packs and other forms.

In plastic extrusion, stainless steel extruder screen is designed for PP, PE and other plastic hot-melt extruding processes. The fine mesh Dutch Weave Wire Cloth Layer together with a Plain Weave Square Mesh support layer forms screen packs are used for preventing impurities in fine extrusion. It is effect to keeps away mixing of foreign particles in finally equipped extrusion product.

Featured Mesh Screen and Filter Strainers, Processed from Stainless Steel Woven Wire Mesh Cloth SUS302, 304, 304L, 316 and 316L:

• Spot Welded Circle or Round Disc Extruder Screens, to be placed into extruder head

• Cylinder Extruder Screen for Thermoplastic polymers

• Leaf Filters

• Multilayer Woven Wire Mesh Extruder Screen Packs of Dutch Weave Wire Cloth Plus Plain Weave Support Filter Mesh

• SS Wire Mesh Filter Disks, with thin frame or rims

• Dutch Reverse Weave Mesh Continuous Filter Belts

• Pleated Candle Filters

• Stainless Steel Wire Mesh Strainers

Woven Wire Mesh Multi Layer Screen Packs

General Types and Materials:

• Woven Wire Cloth Extruder Screen For Plastic Melt Filtration

• Extruder Screens For Polymer Melt Filters

• Stainless Steel Wire Mesh Extruder Filter Discs and Leafs

• Stainless Steel Mesh Extruder Screen Packs

• Wire Cloth Extruder Screens

• Extruder-Screen Packs

• 304 and 316 Stainless Steel Extruder Filter Mesh Discs

• Sintered Wire Cloth Discs and Packs

• Reversed Dutch Weave Stainless Steel Wire Cloth Filter Screen

• Multilayer Extruder Screen Packs With Spot Welded Frames

• Single Layer Net Disc Extruder Screen

Applied in the following fields:

• Plastic and Rubber industry

• Chemical industry

• Aeronautic industries

• Water treatment plant

• Food processing industries

• Petroleum chemical industries.

Wire Mesh (Mainly Stainless Steel) Filter Elements and Strainers

General Types:

Cylinder Filter Cartridges;

Candle Filters;

Stainless Steel Wire Mesh Pleated Filter Elements with Perforated Tube Support Layer;

Temporary Conical Strainers;

Basket Filter Strainers;

Plate Strainers;

Perforated Tubes in Brass and Stainless Steel for Filter Tubing uses;

Tea strainers, colanders, mesh strainers for Kitchen and High temperature uses.

Stainless Steel Wire Mesh, Fine Filter Grade, Filter Media Series:

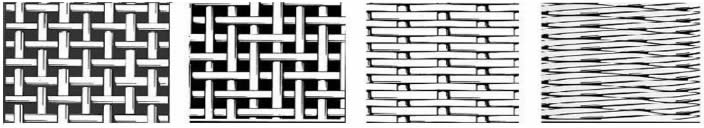

Stainless steel wire mesh is supplied with the following patterns:

Plain, Twill, Dutch Plain, Dutch Twill, Dutch Reverse, Five Heddle. Or multi layer sintered sheet of these ss mesh combined.

Reverse Dutch Weaving Mesh Belt Sizes:

Mesh count | Wire diameter |

260/40 | 0.15mm/0.25mm |

200/40 | 0.17mm/0.27mm |

180/18 | 0.27mm/0.45mm |

132/17 | 0.32mm/0.45mm |

152/24 | 0.27mm/0.40mm |

72/15 | 0.45mm/0.55mm |

Reverse Dutch wire cloth is mainly used in fine extrusion for preventing impurities