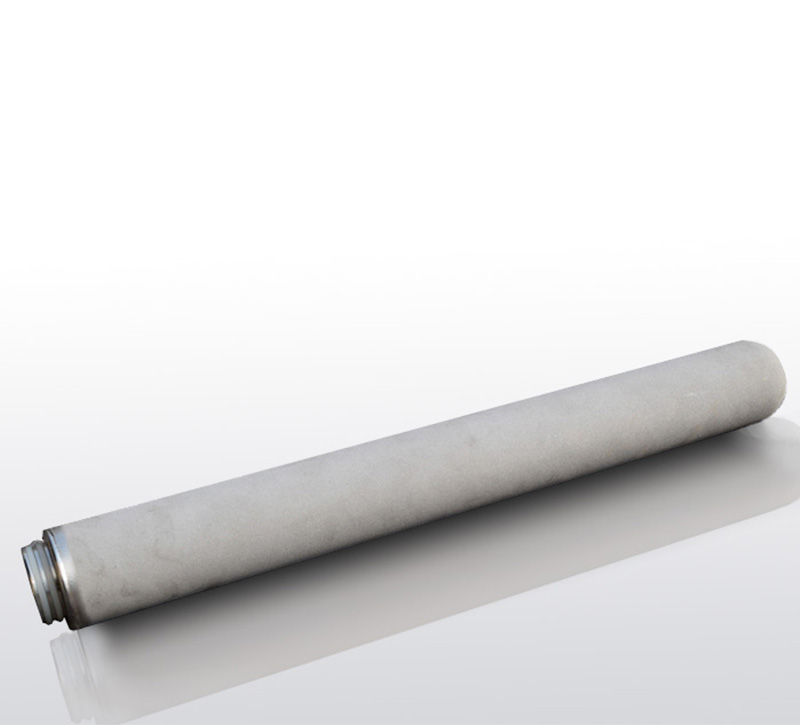

Technical Parameter

Filtration accuracy | 0.22μm 0.45μm 1μm 3μm 5μm 10μm 20μm 30μm 50μm |

Length(Inch) | 10"20"30" |

Porosity | 28-50% |

Compression strength | 0.8Mpa |

Temperature resistance | ≤300℃(Wet) |

Max operating pressure | 0.6Mpa |

Interface | 222 226 M20 Thread |

O ring material | Fluorine rubber, silicone rubber, ethylene propylene rubber |

Filtration Performance

Filtration performance | 50 | 30 | 20 | 10 | 5 | 3 | 2 | 1 |

Relative permeability coefficient(L/cm2.min.pa) | 1×10ˉ3 | 5×10ˉ4 | 1×10ˉ4 | 5×10ˉ5 | 1×10ˉ5 | 5×10ˉ6 | 1×10ˉ6 | 5×10ˉ7 |

Porosity(%) | 35-45 | 35-45 | 35-45 | 35-45 | 35-45 | 35-45 | 35-45 | 35-45 |

Internal pressure failure(Mpa) | ≥0.6 | ≥0.6 | ≥1 | ≥1 | ≥1 | ≥1 | ≥1 | ≥1 |

Application | Coarse particle filtration | Coarse sediment filtration | Coarse sediment filtration | Fine sediment filtration | Fine sediment filtration | Fine sediment filtration | Sterilization filtration | Sterilization filtration |

FEATURES:

1. uniform structure, narrow pore size distribution, high separation efficiency

2. high porosity, small filtration resistance, high penetration efficiency

3. high temperature resistance, generally can be used below 280 degrees

4. good chemical stability, acid and alkali corrosion resistance

5. no particles fall off, do not make the original formation of two pollution, in line with food hygiene and pharmaceutical GMP requirements

6. good mechanical properties, can filter press filtration, simple operation.

7. low pressure, small footprint, large flow

8. the ability of anti microbial, does not interact with microorganisms

9. the molding process is good, the whole welding length of up to 1000 mm

10. can be recycled online, easy to clean, long service life (usually several times the membrane filter)

Interface

Install

Titanium rod filter installation instructions:

1 before the installation of the titanium rod and the shell, the sealing ring must be checked in place, the leakage of the seal ring is strictly prohibited and misplaced

2 for the screw type interface, in the installation of nuts is too much force, to the sealing ring to achieve the role of sealing, in order to prevent the loss of the interface

3 after the installation of the shell, there should be 15 minutes ~20 minutes of cleaning. The inspection process, the cleaning water can be recycled, in order to save costs, to pass the test, the end of the cleaning process

4 normal filtration pressure should be controlled in 0.15~0.25Mpa, if the pressure will greatly increase the difficulty of cleaning effect of anti, backwash effect. The normal use before at least the low-voltage starting time of 3-5 minutes, the pressure gradually increased to 0.15~0.25Mpa, the instantaneous pressure is strictly prohibited.

5 suggested that the titanium rod anti cleaning into the production process, in which each class (8) before the end of the backwash time, each recoil time is 10-20 minutes, backwashing pressure should be gradual, gradually increase the pressure to 0.25~0.3Mpa no instantaneous pressure.

6 when the titanium bar is seriously blocked and the recoil effect is not obvious, ultrasonic cleaning or pickling should be adopted

Cleaning methods

According to several common applications, cleaning methods are as follows:

1. the pharmaceutical and chemical industry in the field of carbon removal filter, we often need to use reverse blowing, back washing method combined with ultrasonic cleaning effect is best

2. the water industry, because the surface of the filter is mostly non water soluble salts and oxides, the general use of 5% nitric acid immersion, without ultrasonic cleaning, cleaning effect can be achieved

3. liquid filtration, combined with the chemical properties of pollutants, respectively, using the following methods for cleaning:

(1) alkali wash: 3-5% hydrogen peroxide solution for 30-60 minutes, temperature of about 40 degrees,

The best in ultrasonic cleaning machines. After soaking with filtered deionized water or water for injection and rushed to neutral, the measured conductivity. With pure air pressure more than 0.4MPa dry.

(2) pickling: soak in a solution of 5% nitric acid for more than 8 hours, with a temperature of about 40 degrees

The best in ultrasonic cleaning machines. After soaking with filtered deionized water or water for injection and washing to neutral, side with pure air conductivity. More than 0.4MPa pressure drying.

(3) organic contamination can be combined with surfactant cleaning, and the system of cell debris pollution is better than that of enzyme cleaning (food and beverage can be cleaned with high concentration of citric acid)

(4) the above methods can be used alone, can also be used in conjunction with each other.